👁️ 0 | 💰 Rs 0.00

0 Comments

0 Shares

0 Reviews

Search

Discover new people, create new connections and make new friends

-

Please log in to like, share and comment!

-

👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Comments 0 Shares 0 Reviews

-

👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Comments 0 Shares 0 Reviews

-

#trees#ui#34#56#7#trees#ui#34#56#7👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Comments 0 Shares 0 Reviews

-

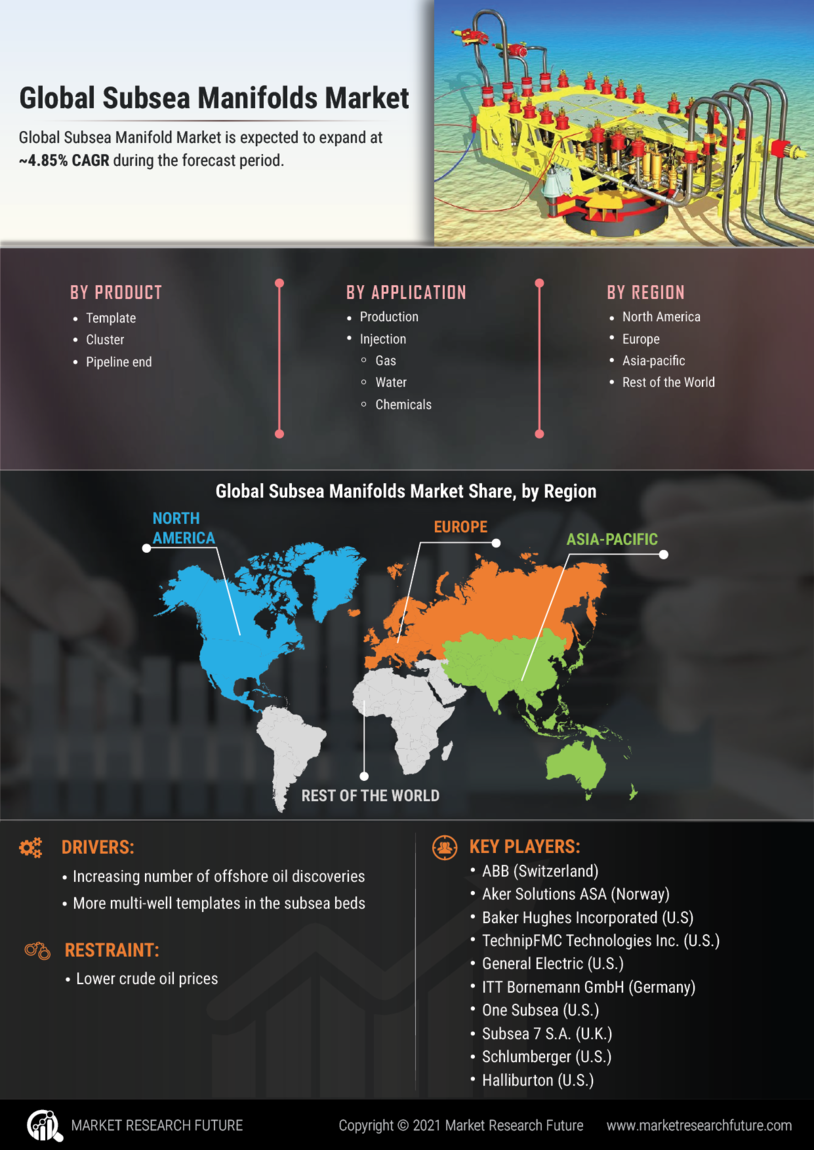

Subsea Production Systems Supporting Offshore Operations

https://www.marketresearchfuture.com/reports/subsea-manifolds-market-3138

As per Market Research Future, subsea production systems

play a critical role in enabling efficient oil and gas extraction from offshore fields, particularly in deepwater and ultra-deepwater environments. These systems are designed to operate on the seabed and manage the flow of hydrocarbons from wells to processing facilities, either on offshore platforms or onshore installations. With increasing exploration activities in challenging offshore locations, subsea production systems have become an essential component of modern energy infrastructure.

Subsea production systems consist of several integrated elements, including subsea trees, manifolds, control systems, umbilicals, flowlines, and risers. Together, these components regulate pressure, control production rates, and ensure safe transportation of oil and gas. Subsea trees, often referred to as “Christmas trees,” are installed on wellheads to control flow and monitor well conditions. Manifolds act as gathering points, combining production from multiple wells into a single flowline, which improves operational efficiency and reduces infrastructure costs.

One of the key drivers behind the adoption of subsea production systems is the shift toward deepwater exploration. As shallow-water reserves mature, energy companies are increasingly focusing on deeper reservoirs that require advanced subsea solutions. These systems allow operators to develop fields that would otherwise be economically or technically unfeasible using traditional platform-based approaches. In addition, subsea tieback solutions enable existing infrastructure to be utilized more effectively by connecting new wells to established facilities.

Technological advancements have significantly enhanced the reliability and performance of subsea production systems. Innovations in digital monitoring, remote operation, and automation have improved real-time data collection and predictive maintenance. Advanced materials and coatings have increased resistance to corrosion and extreme pressures, extending equipment lifespan and reducing downtime. Electrification of subsea systems is also gaining attention, as it supports lower emissions and improved energy efficiency.

Environmental and safety considerations are another important aspect shaping the development of subsea production systems. By placing equipment on the seabed, surface installations are minimized, reducing visual impact and exposure to harsh weather conditions. Enhanced monitoring capabilities help detect leaks or pressure anomalies early, supporting safer operations and environmental protection. These factors are increasingly important as regulatory scrutiny and sustainability expectations continue to rise.

Regionally, subsea production systems are widely deployed in offshore regions such as the North Sea, the Gulf of Mexico, offshore Brazil, and West Africa. Emerging offshore developments in Asia-Pacific are also contributing to market expansion, driven by rising energy demand and ongoing investments in offshore exploration.

Overall, subsea production systems are a cornerstone of offshore oil and gas development. Their ability to support complex field architectures, improve recovery rates, and enhance safety makes them indispensable for meeting global energy needs in challenging offshore environments.

FAQs

What are subsea production systems used for?

They are used to control, process, and transport oil and gas from offshore wells located on the seabed to processing facilities.

Why are subsea production systems important for deepwater fields?

They enable efficient production in deep and ultra-deep waters where surface platforms may be impractical or too costly.

What technologies are improving subsea production systems?

Digital monitoring, automation, advanced materials, and subsea electrification are key technologies enhancing performance and reliability.Subsea Production Systems Supporting Offshore Operations https://www.marketresearchfuture.com/reports/subsea-manifolds-market-3138 As per Market Research Future, subsea production systems play a critical role in enabling efficient oil and gas extraction from offshore fields, particularly in deepwater and ultra-deepwater environments. These systems are designed to operate on the seabed and manage the flow of hydrocarbons from wells to processing facilities, either on offshore platforms or onshore installations. With increasing exploration activities in challenging offshore locations, subsea production systems have become an essential component of modern energy infrastructure. Subsea production systems consist of several integrated elements, including subsea trees, manifolds, control systems, umbilicals, flowlines, and risers. Together, these components regulate pressure, control production rates, and ensure safe transportation of oil and gas. Subsea trees, often referred to as “Christmas trees,” are installed on wellheads to control flow and monitor well conditions. Manifolds act as gathering points, combining production from multiple wells into a single flowline, which improves operational efficiency and reduces infrastructure costs. One of the key drivers behind the adoption of subsea production systems is the shift toward deepwater exploration. As shallow-water reserves mature, energy companies are increasingly focusing on deeper reservoirs that require advanced subsea solutions. These systems allow operators to develop fields that would otherwise be economically or technically unfeasible using traditional platform-based approaches. In addition, subsea tieback solutions enable existing infrastructure to be utilized more effectively by connecting new wells to established facilities. Technological advancements have significantly enhanced the reliability and performance of subsea production systems. Innovations in digital monitoring, remote operation, and automation have improved real-time data collection and predictive maintenance. Advanced materials and coatings have increased resistance to corrosion and extreme pressures, extending equipment lifespan and reducing downtime. Electrification of subsea systems is also gaining attention, as it supports lower emissions and improved energy efficiency. Environmental and safety considerations are another important aspect shaping the development of subsea production systems. By placing equipment on the seabed, surface installations are minimized, reducing visual impact and exposure to harsh weather conditions. Enhanced monitoring capabilities help detect leaks or pressure anomalies early, supporting safer operations and environmental protection. These factors are increasingly important as regulatory scrutiny and sustainability expectations continue to rise. Regionally, subsea production systems are widely deployed in offshore regions such as the North Sea, the Gulf of Mexico, offshore Brazil, and West Africa. Emerging offshore developments in Asia-Pacific are also contributing to market expansion, driven by rising energy demand and ongoing investments in offshore exploration. Overall, subsea production systems are a cornerstone of offshore oil and gas development. Their ability to support complex field architectures, improve recovery rates, and enhance safety makes them indispensable for meeting global energy needs in challenging offshore environments. FAQs What are subsea production systems used for? They are used to control, process, and transport oil and gas from offshore wells located on the seabed to processing facilities. Why are subsea production systems important for deepwater fields? They enable efficient production in deep and ultra-deep waters where surface platforms may be impractical or too costly. What technologies are improving subsea production systems? Digital monitoring, automation, advanced materials, and subsea electrification are key technologies enhancing performance and reliability. WWW.MARKETRESEARCHFUTURE.COMSubsea Manifolds Market Size, Share, Growth Report 2035Subsea Manifolds Market is projected to grow at a 4.8% CAGR from 2025 to 2035, driven by technological advancements, increased offshore exploration, and rising energy demands.👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Comments 0 Shares 0 Reviews

WWW.MARKETRESEARCHFUTURE.COMSubsea Manifolds Market Size, Share, Growth Report 2035Subsea Manifolds Market is projected to grow at a 4.8% CAGR from 2025 to 2035, driven by technological advancements, increased offshore exploration, and rising energy demands.👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Comments 0 Shares 0 Reviews

© 2026 Freecave – Social Media Platform

English

English