-

45 Yazı

-

17 Fotoğraflar

-

0 Videolar

-

Male

-

Ardından: 1 people

© 2026 Freecave – Social Media Platform

Turkish

Turkish

Son Güncellemeler

-

Solid Radioactive Waste Treatment System Market to Grow at a CAGR of 5.8% from 2026 to 2034 – Key Companies to Watch

According to a new report from Intel Market Research,Global Solid Radioactive Waste Treatment System market was valued at USD 3.45 billion in 2025 and is projected to reach USD 5.89 billion by 2034, growing at a CAGR of 5.8% during the forecast period (2026–2034). This growth trajectory reflects increasing nuclear energy adoption globally and the urgent need for advanced waste management solutions across power plants, medical facilities, and research institutions.

What are Solid Radioactive Waste Treatment Systems?

Solid radioactive waste treatment systems represent specialized technologies designed to safely process and contain hazardous materials generated from nuclear operations. These systems employ various methodologies including compaction, incineration, vitrification, and deep geological disposal to reduce volume and ensure long-term environmental safety. With nuclear power generation expanding worldwide, these systems have become critical for regulatory compliance and sustainable operations.

This comprehensive report delivers detailed insights into the global Solid Radioactive Waste Treatment System market, analyzing everything from macroeconomic trends to micro-level competitive dynamics. The study evaluates market size, technological advancements, regulatory frameworks, and strategic opportunities while providing a thorough SWOT and value chain analysis.

The analysis equips stakeholders with actionable intelligence on competitive positioning, helping them identify growth avenues and formulate effective business strategies. By examining market share distribution, product innovations, and operational models of key players, the report serves as an essential tool for strategic decision-making.

For nuclear energy companies, waste management providers, technology developers, and policy makers, this report delivers the critical intelligence needed to navigate this complex and highly regulated market.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/33012/solid-radioactive-waste-treatment-system-market

📥 Download Sample Report: Solid Radioactive Waste Treatment System Market - View in Detailed Research ReportSolid Radioactive Waste Treatment System Market to Grow at a CAGR of 5.8% from 2026 to 2034 – Key Companies to Watch According to a new report from Intel Market Research,Global Solid Radioactive Waste Treatment System market was valued at USD 3.45 billion in 2025 and is projected to reach USD 5.89 billion by 2034, growing at a CAGR of 5.8% during the forecast period (2026–2034). This growth trajectory reflects increasing nuclear energy adoption globally and the urgent need for advanced waste management solutions across power plants, medical facilities, and research institutions. What are Solid Radioactive Waste Treatment Systems? Solid radioactive waste treatment systems represent specialized technologies designed to safely process and contain hazardous materials generated from nuclear operations. These systems employ various methodologies including compaction, incineration, vitrification, and deep geological disposal to reduce volume and ensure long-term environmental safety. With nuclear power generation expanding worldwide, these systems have become critical for regulatory compliance and sustainable operations. This comprehensive report delivers detailed insights into the global Solid Radioactive Waste Treatment System market, analyzing everything from macroeconomic trends to micro-level competitive dynamics. The study evaluates market size, technological advancements, regulatory frameworks, and strategic opportunities while providing a thorough SWOT and value chain analysis. The analysis equips stakeholders with actionable intelligence on competitive positioning, helping them identify growth avenues and formulate effective business strategies. By examining market share distribution, product innovations, and operational models of key players, the report serves as an essential tool for strategic decision-making. For nuclear energy companies, waste management providers, technology developers, and policy makers, this report delivers the critical intelligence needed to navigate this complex and highly regulated market. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/33012/solid-radioactive-waste-treatment-system-market 📥 Download Sample Report: Solid Radioactive Waste Treatment System Market - View in Detailed Research ReportDownload Free Sample : Solid Radioactive Waste Treatment System MarketFree Sample Report Preview: Solid Radioactive Waste Treatment System Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizlemePlease log in to like, share and comment! -

Top 10 Leading Players in the Dry Electrostatic Precipitator System Market Expected to Achieve a 9.6% CAGR by 2034

According to a new report from Intel Market Research, Global Dry Electrostatic Precipitator System market was valued at USD 1.14 billion in 2026 and is projected to reach USD 2.14 billion by 2034, growing at a strong CAGR of 9.6% during the forecast period (2026-2034). This growth is propelled by tightening global emission regulations and rapid industrialization in emerging economies where air pollution control has become a top priority.

What is a Dry Electrostatic Precipitator System?

Dry Electrostatic Precipitators (ESP) are workhorse air pollution control devices that use electrostatic forces to remove particulate matter from industrial exhaust streams. By charging particles through high-voltage electrodes and capturing them on oppositely charged collection plates, these systems achieve removal efficiencies exceeding 99.9% for fine particulate matter (PM2.5), fly ash, and hazardous emissions.

These systems have become indispensable across coal-fired power plants, cement factories, steel mills, and chemical processing facilities, where regulatory compliance demands the most stringent emission controls. While their large footprint and high capital costs present challenges, recent innovations in pulse energization, advanced plate designs, and smart monitoring systems are expanding their adoption.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/33132/dry-electrostatic-precipitator-system-market

📥 Download Sample Report: Dry Electrostatic Precipitator System Market - View in Detailed Research ReportTop 10 Leading Players in the Dry Electrostatic Precipitator System Market Expected to Achieve a 9.6% CAGR by 2034 According to a new report from Intel Market Research, Global Dry Electrostatic Precipitator System market was valued at USD 1.14 billion in 2026 and is projected to reach USD 2.14 billion by 2034, growing at a strong CAGR of 9.6% during the forecast period (2026-2034). This growth is propelled by tightening global emission regulations and rapid industrialization in emerging economies where air pollution control has become a top priority. What is a Dry Electrostatic Precipitator System? Dry Electrostatic Precipitators (ESP) are workhorse air pollution control devices that use electrostatic forces to remove particulate matter from industrial exhaust streams. By charging particles through high-voltage electrodes and capturing them on oppositely charged collection plates, these systems achieve removal efficiencies exceeding 99.9% for fine particulate matter (PM2.5), fly ash, and hazardous emissions. These systems have become indispensable across coal-fired power plants, cement factories, steel mills, and chemical processing facilities, where regulatory compliance demands the most stringent emission controls. While their large footprint and high capital costs present challenges, recent innovations in pulse energization, advanced plate designs, and smart monitoring systems are expanding their adoption. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/33132/dry-electrostatic-precipitator-system-market 📥 Download Sample Report: Dry Electrostatic Precipitator System Market - View in Detailed Research ReportDownload Free Sample : Dry Electrostatic Precipitator System MarketFree Sample Report Preview: Dry Electrostatic Precipitator System Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

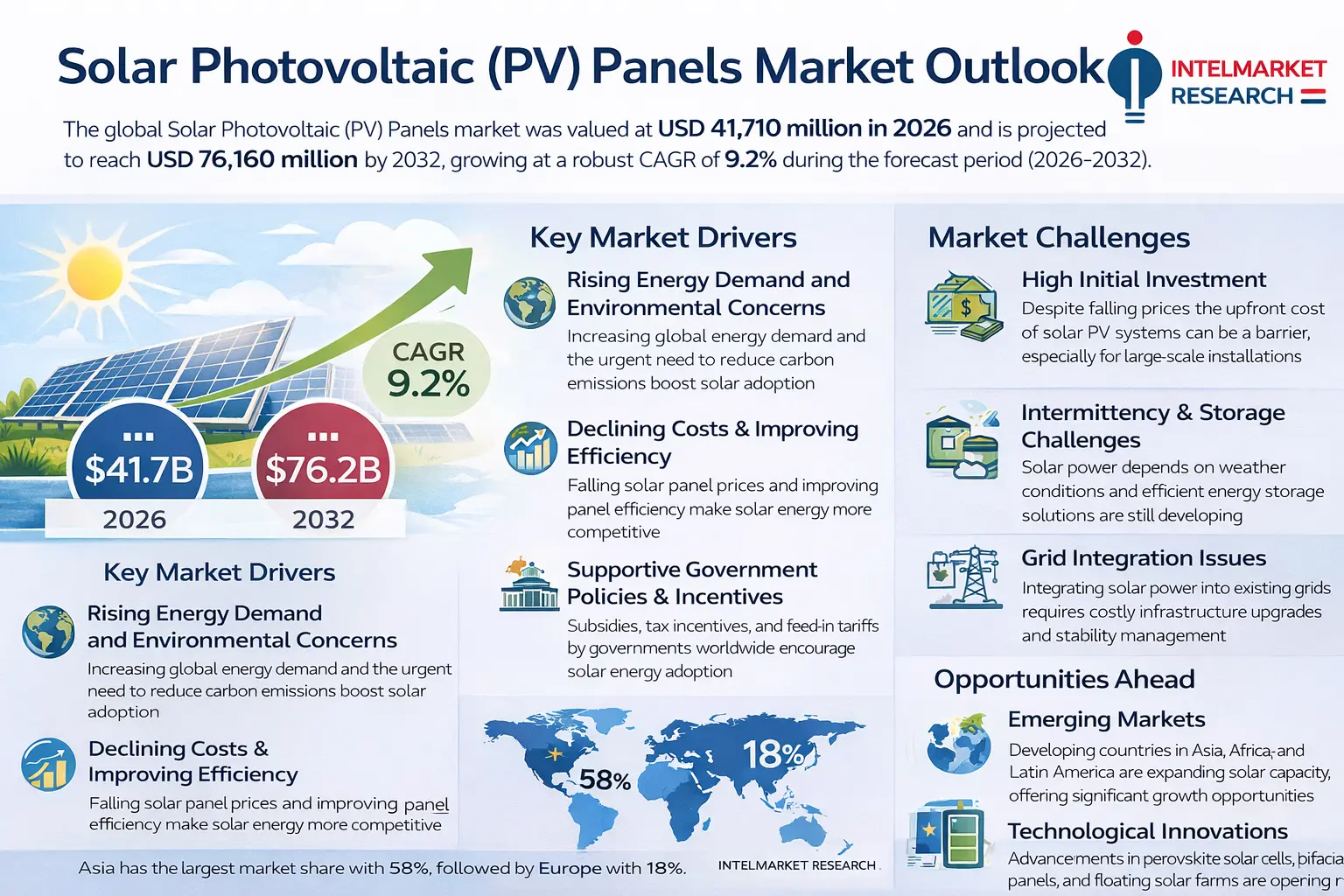

Global Solar Photovoltaic (PV) Panels Market to Reach USD 76,160 Million by 2032, Growing at 9.2% CAGR

What are Solar Photovoltaic (PV) Panels?

A solar cell or photovoltaic (PV) cell is a semiconductor device that converts light directly into electricity by the photovoltaic effect. The most common material in solar cell production is purified silicon that can be applied in different ways. A (Solar Photovoltaic (PV) Panels) PV module is an assembly of photo-voltaic cells mounted in a framework for installation. Photo-voltaic cells use sunlight as a source of energy and generate direct current electricity. A collection of PV modules is called a PV Panel, and a system of Panels is an Array. Arrays of a photovoltaic system supply solar electricity to electrical equipment.

Asia is the largest Solar Photovoltaic (PV) Panels market with about 58% market share. Europe is the follower with about 18% market share.

📥 Download Sample Report: https://www.intelmarketresearch.com/solar-photovoltaic-panels-market-11351Global Solar Photovoltaic (PV) Panels Market to Reach USD 76,160 Million by 2032, Growing at 9.2% CAGR What are Solar Photovoltaic (PV) Panels? A solar cell or photovoltaic (PV) cell is a semiconductor device that converts light directly into electricity by the photovoltaic effect. The most common material in solar cell production is purified silicon that can be applied in different ways. A (Solar Photovoltaic (PV) Panels) PV module is an assembly of photo-voltaic cells mounted in a framework for installation. Photo-voltaic cells use sunlight as a source of energy and generate direct current electricity. A collection of PV modules is called a PV Panel, and a system of Panels is an Array. Arrays of a photovoltaic system supply solar electricity to electrical equipment. Asia is the largest Solar Photovoltaic (PV) Panels market with about 58% market share. Europe is the follower with about 18% market share. 📥 Download Sample Report: https://www.intelmarketresearch.com/solar-photovoltaic-panels-market-11351👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Fixed Floating Solar Panels Market Size & Share Analysis 2026–2034

According to a new report from Intel Market Research, Global Fixed Floating Solar Panels market was valued at USD 109 million in 2025 and is projected to reach USD 167 million by 2034, growing at a steady CAGR of 6.3% during the forecast period (2026–2034). This growth is driven by increasing renewable energy demand, land conservation needs, and technological innovations in photovoltaic systems.

What are Fixed Floating Solar Panels?

Fixed floating solar panels are photovoltaic systems mounted on stationary platforms deployed on water bodies such as reservoirs, lakes, and other calm water surfaces. Unlike ground-mounted solar installations, these systems utilize underutilized water surfaces, making them ideal for regions with limited land availability. The technology offers dual benefits of energy generation and reduced water evaporation, particularly valuable in water-scarce regions.

This report provides comprehensive insights into the global Fixed Floating Solar Panels market, covering market dynamics, competitive landscape, key applications, and regional analysis. The study helps stakeholders understand market opportunities, technological trends, and strategic imperatives in this evolving sector.

📥 Download FREE Sample Report: https://www.intelmarketresearch.com/download-free-sample/25425/fixed-floating-solar-panels-market

📥 Download FREE Sample Report: Fixed Floating Solar Panels Market - View in Detailed Research ReportFixed Floating Solar Panels Market Size & Share Analysis 2026–2034 According to a new report from Intel Market Research, Global Fixed Floating Solar Panels market was valued at USD 109 million in 2025 and is projected to reach USD 167 million by 2034, growing at a steady CAGR of 6.3% during the forecast period (2026–2034). This growth is driven by increasing renewable energy demand, land conservation needs, and technological innovations in photovoltaic systems. What are Fixed Floating Solar Panels? Fixed floating solar panels are photovoltaic systems mounted on stationary platforms deployed on water bodies such as reservoirs, lakes, and other calm water surfaces. Unlike ground-mounted solar installations, these systems utilize underutilized water surfaces, making them ideal for regions with limited land availability. The technology offers dual benefits of energy generation and reduced water evaporation, particularly valuable in water-scarce regions. This report provides comprehensive insights into the global Fixed Floating Solar Panels market, covering market dynamics, competitive landscape, key applications, and regional analysis. The study helps stakeholders understand market opportunities, technological trends, and strategic imperatives in this evolving sector. 📥 Download FREE Sample Report: https://www.intelmarketresearch.com/download-free-sample/25425/fixed-floating-solar-panels-market 📥 Download FREE Sample Report: Fixed Floating Solar Panels Market - View in Detailed Research Report👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Global Fire Safe Ball Valve Market Size, Share & CAGR Forecast 2026–2034

According to a new report from Intel Market Research,Global Fire Safe Ball Valve market was valued at USD 1.45 billion in 2025 and is projected to reach USD 2.85 billion by 2034, growing at a CAGR of 7.8% during the forecast period (2026-2034). This growth trajectory reflects increasing industrialization and stringent safety mandates across critical infrastructure sectors.

What are Fire Safe Ball Valves?

Fire Safe Ball Valves represent mission-critical components in industrial fluid control systems, specifically engineered to maintain sealing integrity during fire emergencies. These valves incorporate advanced sealing mechanisms - typically graphite or metal-to-metal seats - that prevent catastrophic failures when exposed to extreme temperatures exceeding 1000°F. Unlike standard ball valves, their fire-safe design ensures zero leakage even when elastomeric seals degrade, making them non-negotiable in hydrocarbon processing, power plants, and chemical manufacturing facilities.

The market has evolved beyond basic safety compliance, with modern iterations featuring:

Fail-safe actuators that automatically close during emergencies

Graphite-enhanced sealing systems with 50% longer service intervals

API 607/ISO 10497 certified designs meeting global safety benchmarks

This report delivers a 360-degree analysis of the Fire Safe Ball Valve ecosystem, from macro industry trends to micro-level competitive dynamics, equipping stakeholders with actionable intelligence for strategic planning.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32666/fire-safe-ball-valve-market

📥 Download Sample Report: Fire Safe Ball Valve Market - View in Detailed Research ReportGlobal Fire Safe Ball Valve Market Size, Share & CAGR Forecast 2026–2034 According to a new report from Intel Market Research,Global Fire Safe Ball Valve market was valued at USD 1.45 billion in 2025 and is projected to reach USD 2.85 billion by 2034, growing at a CAGR of 7.8% during the forecast period (2026-2034). This growth trajectory reflects increasing industrialization and stringent safety mandates across critical infrastructure sectors. What are Fire Safe Ball Valves? Fire Safe Ball Valves represent mission-critical components in industrial fluid control systems, specifically engineered to maintain sealing integrity during fire emergencies. These valves incorporate advanced sealing mechanisms - typically graphite or metal-to-metal seats - that prevent catastrophic failures when exposed to extreme temperatures exceeding 1000°F. Unlike standard ball valves, their fire-safe design ensures zero leakage even when elastomeric seals degrade, making them non-negotiable in hydrocarbon processing, power plants, and chemical manufacturing facilities. The market has evolved beyond basic safety compliance, with modern iterations featuring: Fail-safe actuators that automatically close during emergencies Graphite-enhanced sealing systems with 50% longer service intervals API 607/ISO 10497 certified designs meeting global safety benchmarks This report delivers a 360-degree analysis of the Fire Safe Ball Valve ecosystem, from macro industry trends to micro-level competitive dynamics, equipping stakeholders with actionable intelligence for strategic planning. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32666/fire-safe-ball-valve-market 📥 Download Sample Report: Fire Safe Ball Valve Market - View in Detailed Research ReportDownload Free Sample : Fire Safe Ball Valve MarketFree Sample Report Preview: Fire Safe Ball Valve Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Why Is the Automatic Bottle Labeling Machine Market Gaining Rapid Demand Globally?

According to a new report from Intel Market Research, Global Automatic Bottle Labeling Machine market was valued at USD 1.85 billion in 2025 and is projected to reach USD 3.12 billion by 2034, growing at a CAGR of 6.7% during the forecast period (2026–2034). This growth is driven by increasing automation in packaging lines, stringent labeling regulations across industries, and technological advancements in labeling equipment.

What is an Automatic Bottle Labeling Machine?

Automatic bottle labeling machines are precision packaging systems designed to apply labels onto bottles with high accuracy and speed. These machines support various labeling technologies including self-adhesive, shrink sleeve, glue-based, and in-mold labeling, serving diverse industries from beverages to pharmaceuticals. Their automated operation significantly reduces human error while increasing production throughput, making them indispensable in modern manufacturing facilities.

This report offers comprehensive insights into the automatic bottle labeling machine market, covering everything from macro industry trends to micro-level competitive analysis. We examine market size data, segmentation, regional dynamics, and technological innovations that are shaping this sector.

The analysis enables businesses to understand competitive pressures and identify strategies for growth. It also provides frameworks for evaluating operational positioning within this rapidly evolving market. With detailed profiles of leading manufacturers and emerging players, the report helps stakeholders benchmark their performance against industry standards.

For businesses operating in packaging, manufacturing, or related sectors, this report delivers essential intelligence to inform strategic decision-making and capital investments.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32605/automatic-bottle-labeling-machine-market

📥 Download Sample Report: Automatic Bottle Labeling Machine Market - View in Detailed Research ReportWhy Is the Automatic Bottle Labeling Machine Market Gaining Rapid Demand Globally? According to a new report from Intel Market Research, Global Automatic Bottle Labeling Machine market was valued at USD 1.85 billion in 2025 and is projected to reach USD 3.12 billion by 2034, growing at a CAGR of 6.7% during the forecast period (2026–2034). This growth is driven by increasing automation in packaging lines, stringent labeling regulations across industries, and technological advancements in labeling equipment. What is an Automatic Bottle Labeling Machine? Automatic bottle labeling machines are precision packaging systems designed to apply labels onto bottles with high accuracy and speed. These machines support various labeling technologies including self-adhesive, shrink sleeve, glue-based, and in-mold labeling, serving diverse industries from beverages to pharmaceuticals. Their automated operation significantly reduces human error while increasing production throughput, making them indispensable in modern manufacturing facilities. This report offers comprehensive insights into the automatic bottle labeling machine market, covering everything from macro industry trends to micro-level competitive analysis. We examine market size data, segmentation, regional dynamics, and technological innovations that are shaping this sector. The analysis enables businesses to understand competitive pressures and identify strategies for growth. It also provides frameworks for evaluating operational positioning within this rapidly evolving market. With detailed profiles of leading manufacturers and emerging players, the report helps stakeholders benchmark their performance against industry standards. For businesses operating in packaging, manufacturing, or related sectors, this report delivers essential intelligence to inform strategic decision-making and capital investments. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32605/automatic-bottle-labeling-machine-market 📥 Download Sample Report: Automatic Bottle Labeling Machine Market - View in Detailed Research ReportDownload Free Sample : Automatic Bottle Labeling Machine MarketFree Sample Report Preview: Automatic Bottle Labeling Machine Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Global Lightweight Robots Market Size, Share & CAGR Forecast 2026–2034

According to a new report from Intel Market Research, Global Lightweight Robots market was valued at USD 3.35 billion in 2025 and is projected to reach USD 8.27 billion by 2034, growing at a CAGR of 14.1% during the forecast period (2026-2034). This substantial growth is being driven by increasing automation across industries, advancements in collaborative robotics (cobots), and the growing need for flexible manufacturing solutions.

What are Lightweight Robots?

Lightweight robots, also known as LBR (lightweight robotic) arms, are industrial automation solutions designed with a superior payload-to-weight ratio (typically 1:2 compared to traditional industrial robots' 1:8). These innovative robotic systems mimic human arm movements with remarkable precision, offering unprecedented flexibility and ease of integration across various industrial applications. Particularly valued for performing repetitive or ergonomically challenging tasks, lightweight robots are transforming operations in sectors from automotive manufacturing to precision healthcare procedures.

This comprehensive report provides an in-depth analysis of the global Lightweight Robots market, covering critical aspects from competitive dynamics to emerging technological trends. It examines market size projections, key growth drivers, sector-specific challenges, and regional adoption patterns that are reshaping industrial automation strategies worldwide.

The analysis enables businesses to identify competitive advantages, assess market positioning, and develop data-driven automation strategies. The report also highlights the evolving competitive landscape, providing market share insights, product positioning analysis, and performance metrics for leading robotic automation providers.

📥 Download FREE Sample Report: https://www.intelmarketresearch.com/download-free-sample/32592/lightweight-robots-market

📥 Download FREE Sample Report: Lightweight Robots Market - View in Detailed Research ReportGlobal Lightweight Robots Market Size, Share & CAGR Forecast 2026–2034 According to a new report from Intel Market Research, Global Lightweight Robots market was valued at USD 3.35 billion in 2025 and is projected to reach USD 8.27 billion by 2034, growing at a CAGR of 14.1% during the forecast period (2026-2034). This substantial growth is being driven by increasing automation across industries, advancements in collaborative robotics (cobots), and the growing need for flexible manufacturing solutions. What are Lightweight Robots? Lightweight robots, also known as LBR (lightweight robotic) arms, are industrial automation solutions designed with a superior payload-to-weight ratio (typically 1:2 compared to traditional industrial robots' 1:8). These innovative robotic systems mimic human arm movements with remarkable precision, offering unprecedented flexibility and ease of integration across various industrial applications. Particularly valued for performing repetitive or ergonomically challenging tasks, lightweight robots are transforming operations in sectors from automotive manufacturing to precision healthcare procedures. This comprehensive report provides an in-depth analysis of the global Lightweight Robots market, covering critical aspects from competitive dynamics to emerging technological trends. It examines market size projections, key growth drivers, sector-specific challenges, and regional adoption patterns that are reshaping industrial automation strategies worldwide. The analysis enables businesses to identify competitive advantages, assess market positioning, and develop data-driven automation strategies. The report also highlights the evolving competitive landscape, providing market share insights, product positioning analysis, and performance metrics for leading robotic automation providers. 📥 Download FREE Sample Report: https://www.intelmarketresearch.com/download-free-sample/32592/lightweight-robots-market 📥 Download FREE Sample Report: Lightweight Robots Market - View in Detailed Research ReportDownload Free Sample : Lightweight Robots MarketFree Sample Report Preview: Lightweight Robots Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Why Is the Textile Embroidery Machine Market Gaining Rapid Demand Globally?

According to a new report from Intel Market Research, the global Textile Embroidery Machine market was valued at USD 2.17 billion in 2026 and is projected to reach USD 3.12 billion by 2034, growing at a CAGR of 3.1% during the forecast period (2026-2034). This growth is driven by increasing demand for customized apparel, technological advancements in automation, and expansion of the textile industry globally.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32568/textile-embroidery-machine-market

📥 Download Sample Report: Textile Embroidery Machine Market - View in Detailed Research Report

What are Textile Embroidery Machines?

Textile embroidery machines are advanced automated systems designed to stitch intricate patterns onto fabrics with precision and efficiency. These systems have evolved from traditional manual operations to computer-controlled units capable of executing complex designs through digital patterns. Modern variants include single-head, multi-head, flat embroidery, and cap embroidery machines serving diverse industrial and commercial applications.

The market report provides comprehensive analysis covering all essential aspects - from macro market overview to micro details including competitive landscape, development trends, niche markets, key drivers, challenges, and future opportunities. The analysis helps industry participants understand competitive dynamics while offering strategic frameworks for business evaluation.

Key Market Drivers

1. Growing Demand for Customized Textile Products

The market is experiencing significant growth due to increasing consumer preference for personalized apparel and home textiles. Manufacturers are adopting advanced embroidery machines to meet this demand, with the market growing approximately 7.8% annually. The rise of e-commerce platforms has accelerated this trend by making customized products more accessible to consumers globally.

2. Technological Advancements in Embroidery Equipment

Modern textile embroidery machines now incorporate AI-powered designs, multi-head configurations, and IoT connectivity, enhancing production efficiency by up to 35%. These innovations allow businesses to reduce operational costs while improving output quality. The Asian market accounted for 42% of global sales in 2023, driven by expanding garment industries in China and India.

3. Expansion of Textile Industry

The growing textile sector across emerging economies continues to drive demand for embroidery machines. Key technological integrations like cloud-based design libraries and automated thread trimming are transforming production workflows while meeting evolving consumer preferences.

Market Challenges

High Initial Investment Costs - Industrial-grade machines costing $15,000-$80,000 create barriers for small manufacturers

Skilled Labor Shortage - Operating advanced machinery requires specialized training that's scarce in many regions

Fluctuating Raw Material Prices - Recent market analysis shows 12-15% fluctuation in thread and fabric costs

Emerging Opportunities

The textile embroidery machine market presents several growth opportunities:

Technical Textiles - Growing demand in medical, automotive and industrial applications projected to reach $2.3 billion by 2026

Smart Manufacturing - Integration of IoT and AI for predictive maintenance and quality control

Sustainable Solutions - Development of energy-efficient models compatible with eco-friendly materials

📥 Download Sample Report: Textile Embroidery Machine Market - View in Detailed Research ReportWhy Is the Textile Embroidery Machine Market Gaining Rapid Demand Globally? According to a new report from Intel Market Research, the global Textile Embroidery Machine market was valued at USD 2.17 billion in 2026 and is projected to reach USD 3.12 billion by 2034, growing at a CAGR of 3.1% during the forecast period (2026-2034). This growth is driven by increasing demand for customized apparel, technological advancements in automation, and expansion of the textile industry globally. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32568/textile-embroidery-machine-market 📥 Download Sample Report: Textile Embroidery Machine Market - View in Detailed Research Report What are Textile Embroidery Machines? Textile embroidery machines are advanced automated systems designed to stitch intricate patterns onto fabrics with precision and efficiency. These systems have evolved from traditional manual operations to computer-controlled units capable of executing complex designs through digital patterns. Modern variants include single-head, multi-head, flat embroidery, and cap embroidery machines serving diverse industrial and commercial applications. The market report provides comprehensive analysis covering all essential aspects - from macro market overview to micro details including competitive landscape, development trends, niche markets, key drivers, challenges, and future opportunities. The analysis helps industry participants understand competitive dynamics while offering strategic frameworks for business evaluation. Key Market Drivers 1. Growing Demand for Customized Textile Products The market is experiencing significant growth due to increasing consumer preference for personalized apparel and home textiles. Manufacturers are adopting advanced embroidery machines to meet this demand, with the market growing approximately 7.8% annually. The rise of e-commerce platforms has accelerated this trend by making customized products more accessible to consumers globally. 2. Technological Advancements in Embroidery Equipment Modern textile embroidery machines now incorporate AI-powered designs, multi-head configurations, and IoT connectivity, enhancing production efficiency by up to 35%. These innovations allow businesses to reduce operational costs while improving output quality. The Asian market accounted for 42% of global sales in 2023, driven by expanding garment industries in China and India. 3. Expansion of Textile Industry The growing textile sector across emerging economies continues to drive demand for embroidery machines. Key technological integrations like cloud-based design libraries and automated thread trimming are transforming production workflows while meeting evolving consumer preferences. Market Challenges High Initial Investment Costs - Industrial-grade machines costing $15,000-$80,000 create barriers for small manufacturers Skilled Labor Shortage - Operating advanced machinery requires specialized training that's scarce in many regions Fluctuating Raw Material Prices - Recent market analysis shows 12-15% fluctuation in thread and fabric costs Emerging Opportunities The textile embroidery machine market presents several growth opportunities: Technical Textiles - Growing demand in medical, automotive and industrial applications projected to reach $2.3 billion by 2026 Smart Manufacturing - Integration of IoT and AI for predictive maintenance and quality control Sustainable Solutions - Development of energy-efficient models compatible with eco-friendly materials 📥 Download Sample Report: Textile Embroidery Machine Market - View in Detailed Research ReportDownload Free Sample : Textile Embroidery Machine MarketFree Sample Report Preview: Textile Embroidery Machine Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Why Is the Sewer Equipment Market Gaining Rapid Demand Globally?

According to a new report from Intel Market Research, Global Sewer Equipment market was valued at USD 3.45 billion in 2025 and is projected to reach USD 5.89 billion by 2034, growing at a CAGR of 5.8% during the forecast period (2026-2034). This growth is driven by urbanization trends, aging infrastructure rehabilitation needs, and technological advancements in wastewater management systems.

Sewer equipment includes specialized machinery for maintaining, inspecting, and repairing sewer systems - from high-pressure jetting machines to robotic inspection crawlers. These solutions have become indispensable for municipalities and industrial facilities dealing with increasing wastewater volumes and regulatory requirements.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32543/sewer-equipment-market

Understanding Sewer Equipment

Sewer equipment encompasses mechanical systems designed to address the complex challenges of modern wastewater infrastructure. From hydro-jetting trucks that clear stubborn blockages to remotely operated inspection cameras that assess pipe conditions without excavation, these technologies form the backbone of efficient municipal and industrial wastewater management.

Municipalities increasingly rely on advanced equipment like vacuum excavation systems that combine suction capabilities with precision digging - significantly reducing the risks associated with traditional excavation methods near underground utilities. Similarly, trenchless rehabilitation technologies allow repairs without disruptive digging, preserving roads and landscapes while maintaining sewer functionality.

This report provides comprehensive analysis of the sewer equipment market, covering everything from macroeconomic trends to detailed competitive intelligence. It helps stakeholders understand:

Market size projections and growth opportunities

Technological innovations shaping the industry

Competitive strategies of leading manufacturers

Regional infrastructure development patterns

Regulatory impacts on equipment adoption

📘 Get Full Report: Sewer Equipment Market - View Detailed Research ReportWhy Is the Sewer Equipment Market Gaining Rapid Demand Globally? According to a new report from Intel Market Research, Global Sewer Equipment market was valued at USD 3.45 billion in 2025 and is projected to reach USD 5.89 billion by 2034, growing at a CAGR of 5.8% during the forecast period (2026-2034). This growth is driven by urbanization trends, aging infrastructure rehabilitation needs, and technological advancements in wastewater management systems. Sewer equipment includes specialized machinery for maintaining, inspecting, and repairing sewer systems - from high-pressure jetting machines to robotic inspection crawlers. These solutions have become indispensable for municipalities and industrial facilities dealing with increasing wastewater volumes and regulatory requirements. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32543/sewer-equipment-market Understanding Sewer Equipment Sewer equipment encompasses mechanical systems designed to address the complex challenges of modern wastewater infrastructure. From hydro-jetting trucks that clear stubborn blockages to remotely operated inspection cameras that assess pipe conditions without excavation, these technologies form the backbone of efficient municipal and industrial wastewater management. Municipalities increasingly rely on advanced equipment like vacuum excavation systems that combine suction capabilities with precision digging - significantly reducing the risks associated with traditional excavation methods near underground utilities. Similarly, trenchless rehabilitation technologies allow repairs without disruptive digging, preserving roads and landscapes while maintaining sewer functionality. This report provides comprehensive analysis of the sewer equipment market, covering everything from macroeconomic trends to detailed competitive intelligence. It helps stakeholders understand: Market size projections and growth opportunities Technological innovations shaping the industry Competitive strategies of leading manufacturers Regional infrastructure development patterns Regulatory impacts on equipment adoption 📘 Get Full Report: Sewer Equipment Market - View Detailed Research ReportDownload Free Sample : Sewer Equipment MarketFree Sample Report Preview: Sewer Equipment Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Which Regions Will Dominate the 3 Point Bending Test Machine Market by 2034?

According to a new report from Intel Market Research,Global 3 Point Bending Test Machine market was valued at USD 420 million in 2025 and is projected to reach USD 680 million by 2034, growing at a steady CAGR of 5.3% during the forecast period (2026-2034). This growth is fueled by increasing industrial quality control demands and the rising adoption of advanced material testing across aerospace, automotive and construction sectors.

What is a 3 Point Bending Test Machine?

3 Point Bending Test Machines are precision instruments designed to evaluate the flexural strength and stiffness of materials through a controlled three-point loading mechanism. These machines play a critical role in material characterization by measuring key parameters including modulus of elasticity, yield strength and deflection under standardized test conditions. The technology is particularly valuable for quality assurance in industries where material performance directly impacts product safety and reliability.

Applications span from traditional material testing to cutting-edge composite analysis, with modern machines increasingly incorporating digital interfaces and automated features. As manufacturing standards become more stringent globally, these testing systems have become indispensable for R&D and production quality control across multiple industries.

📥 Download Sample Report: 3 Point Bending Test Machine Market - View in Detailed Research Report

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32525/point-bending-test-machine-marketWhich Regions Will Dominate the 3 Point Bending Test Machine Market by 2034? According to a new report from Intel Market Research,Global 3 Point Bending Test Machine market was valued at USD 420 million in 2025 and is projected to reach USD 680 million by 2034, growing at a steady CAGR of 5.3% during the forecast period (2026-2034). This growth is fueled by increasing industrial quality control demands and the rising adoption of advanced material testing across aerospace, automotive and construction sectors. What is a 3 Point Bending Test Machine? 3 Point Bending Test Machines are precision instruments designed to evaluate the flexural strength and stiffness of materials through a controlled three-point loading mechanism. These machines play a critical role in material characterization by measuring key parameters including modulus of elasticity, yield strength and deflection under standardized test conditions. The technology is particularly valuable for quality assurance in industries where material performance directly impacts product safety and reliability. Applications span from traditional material testing to cutting-edge composite analysis, with modern machines increasingly incorporating digital interfaces and automated features. As manufacturing standards become more stringent globally, these testing systems have become indispensable for R&D and production quality control across multiple industries. 📥 Download Sample Report: 3 Point Bending Test Machine Market - View in Detailed Research Report 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32525/point-bending-test-machine-marketDownload Free Sample : 3 Point Bending Test Machine MarketFree Sample Report Preview: 3 Point Bending Test Machine Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Global Aerospace Reservoir Market Size, Share & CAGR Forecast 2026–2034

According to a new report from Intel Market Research, Global Aerospace Reservoir market was valued at USD 1.75 billion in 2025 and is projected to reach USD 3.15 billion by 2034, growing at a CAGR of 6.8% during the forecast period (2026–2034). This growth is driven by increasing aircraft production, fleet modernization programs, and advancements in lightweight composite materials for reservoir manufacturing.

What are Aerospace Reservoirs?

Aerospace reservoirs are critical fluid management components in aircraft hydraulic and fuel systems, designed to store and regulate fluids under extreme pressure conditions. These systems include hydraulic reservoirs, fuel reservoirs, and specialized storage units that ensure operational reliability across commercial, military, and space applications. Modern designs increasingly incorporate composite materials to reduce weight while maintaining structural integrity under demanding flight conditions.

This report provides comprehensive analysis of the global Aerospace Reservoir market, covering size projections, competitive dynamics, technological trends, and regional developments. The research examines how material innovations and regulatory requirements shape reservoir design while addressing key challenges in supply chain management and certification processes.

The competitive analysis helps industry participants benchmark their market position, while segmentation insights reveal high-growth opportunities. For aviation engineers, procurement specialists, and aerospace executives, this report delivers actionable intelligence on emerging technologies and strategic partnerships shaping fluid system architecture.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32520/aerospace-reservoir-market

📘 Get Full Report Here: Aerospace Reservoir Market - View Detailed Research ReportGlobal Aerospace Reservoir Market Size, Share & CAGR Forecast 2026–2034 According to a new report from Intel Market Research, Global Aerospace Reservoir market was valued at USD 1.75 billion in 2025 and is projected to reach USD 3.15 billion by 2034, growing at a CAGR of 6.8% during the forecast period (2026–2034). This growth is driven by increasing aircraft production, fleet modernization programs, and advancements in lightweight composite materials for reservoir manufacturing. What are Aerospace Reservoirs? Aerospace reservoirs are critical fluid management components in aircraft hydraulic and fuel systems, designed to store and regulate fluids under extreme pressure conditions. These systems include hydraulic reservoirs, fuel reservoirs, and specialized storage units that ensure operational reliability across commercial, military, and space applications. Modern designs increasingly incorporate composite materials to reduce weight while maintaining structural integrity under demanding flight conditions. This report provides comprehensive analysis of the global Aerospace Reservoir market, covering size projections, competitive dynamics, technological trends, and regional developments. The research examines how material innovations and regulatory requirements shape reservoir design while addressing key challenges in supply chain management and certification processes. The competitive analysis helps industry participants benchmark their market position, while segmentation insights reveal high-growth opportunities. For aviation engineers, procurement specialists, and aerospace executives, this report delivers actionable intelligence on emerging technologies and strategic partnerships shaping fluid system architecture. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32520/aerospace-reservoir-market 📘 Get Full Report Here: Aerospace Reservoir Market - View Detailed Research ReportDownload Free Sample : Aerospace Reservoir MarketFree Sample Report Preview: Aerospace Reservoir Market Growth Analysis, Dynamics, Key Players and Innovations, Outlook and Forecast 2026-2034👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme -

Global Compact Electro-Hydraulic Actuator Market Size, Share & Forecast 2026–2034

According to a new report from Intel Market Research, Global compact electro-hydraulic actuator market was valued at USD 1.85 billion in 2026 and is projected to reach USD 3.45 billion by 2034, growing at a steady CAGR of 6.8% during the forecast period (2026-2034). This growth trajectory reflects the increasing demand for precision motion control solutions across industrial automation, aerospace, and heavy machinery sectors where space constraints and power density are critical considerations.

What are Compact Electro-Hydraulic Actuators?

Compact electro-hydraulic actuators represent a sophisticated fusion of hydraulic power and electronic control systems, combining servo valves, hydraulic cylinders, and advanced feedback sensors in space-optimized packages. These high-performance motion control devices deliver precise force application and positioning capabilities that outperform conventional hydraulic systems while fitting into tight installation spaces that would challenge traditional actuators.

This comprehensive market report provides strategic insights into the global compact electro-hydraulic actuator landscape, analyzing market dynamics from macro industry trends to micro-level competitive developments. The study examines technological innovations, application-specific adoption patterns, and regional market behaviors to help stakeholders identify growth opportunities and optimize market positioning strategies.

The report serves as an essential resource for OEMs, system integrators, engineering firms, and investors seeking to understand the competitive environment, technological advancements, and evolving application needs in this specialized motion control segment.

📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32479/compact-electro-hydraulic-actuator-marketGlobal Compact Electro-Hydraulic Actuator Market Size, Share & Forecast 2026–2034 According to a new report from Intel Market Research, Global compact electro-hydraulic actuator market was valued at USD 1.85 billion in 2026 and is projected to reach USD 3.45 billion by 2034, growing at a steady CAGR of 6.8% during the forecast period (2026-2034). This growth trajectory reflects the increasing demand for precision motion control solutions across industrial automation, aerospace, and heavy machinery sectors where space constraints and power density are critical considerations. What are Compact Electro-Hydraulic Actuators? Compact electro-hydraulic actuators represent a sophisticated fusion of hydraulic power and electronic control systems, combining servo valves, hydraulic cylinders, and advanced feedback sensors in space-optimized packages. These high-performance motion control devices deliver precise force application and positioning capabilities that outperform conventional hydraulic systems while fitting into tight installation spaces that would challenge traditional actuators. This comprehensive market report provides strategic insights into the global compact electro-hydraulic actuator landscape, analyzing market dynamics from macro industry trends to micro-level competitive developments. The study examines technological innovations, application-specific adoption patterns, and regional market behaviors to help stakeholders identify growth opportunities and optimize market positioning strategies. The report serves as an essential resource for OEMs, system integrators, engineering firms, and investors seeking to understand the competitive environment, technological advancements, and evolving application needs in this specialized motion control segment. 📥 Download Sample Report: https://www.intelmarketresearch.com/download-free-sample/32479/compact-electro-hydraulic-actuator-market👁️ 0 | 💰 Rs 0.00⚡ First 24h Boost (+%) • left0 Yorumlar 0 hisse senetleri 0 önizleme

Daha Hikayeler